TotalEnergies lubricants for general maintenance in car manufacturing industry

TotalEnergies operates in more than 150 countries via its network of subsidiaries and distributors, guaranteeing you a robust and local supply chain thanks to a dedicated team at your service.

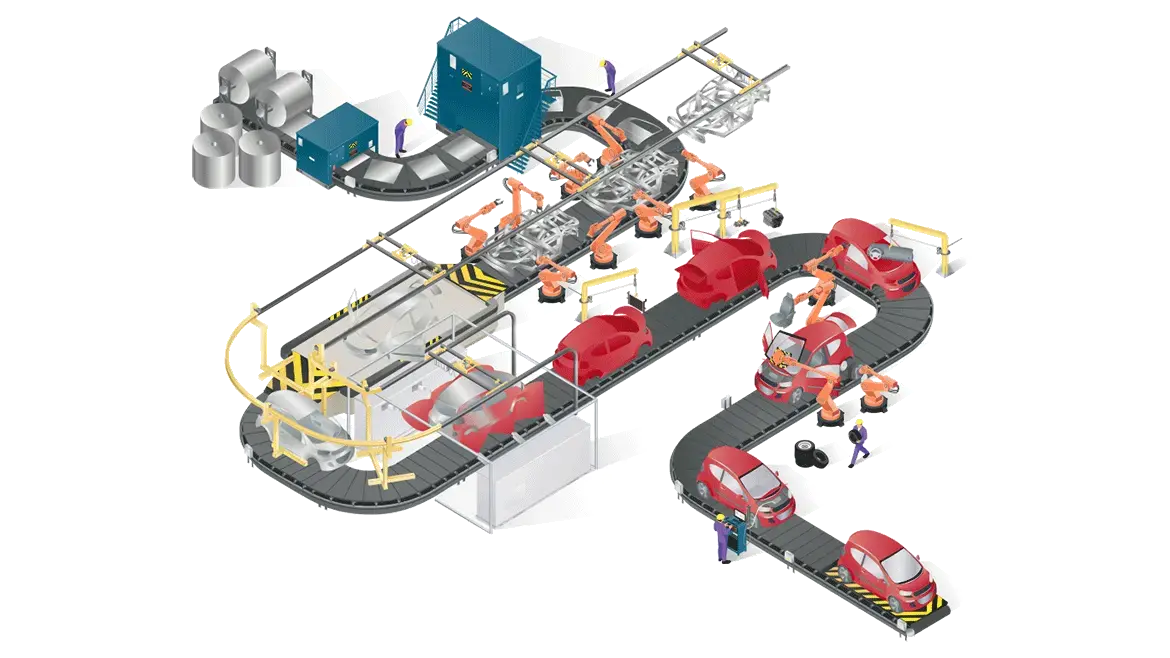

We offer a range of innovative lubricants to optimize industrial processes. Ensuring safety and compatibility with technological requirements, TotalEnergies Lubrifiants’ products are used at all stages of the car and car parts (Tier1) manufacturing process. Based on the latest technologies, we offer customized solutions allowing optimum reliability of your production and lower consumption.

Automotive manufacturing catalog

Discover our catalogOur lubricants for general maintenance in car manufacturing industry

The reliability and efficiency of your industrial equipments is our priority. TotalEnergies Lubrifiants is developing specific product ranges to lubricate every single point of your process, targeting the highest performance level. Our products are constantly improved in order to reduce your operational costs, increase the safety of your operators and protect the environment by reducing our global footprint.

Specialty lubricants for automotive industry

LUBRILOG is a specific brand of TotalEnergies Lubricants which develop specialty products for the automotive industry

Our lubricants for overhead conveyors in car manufacturing industry: Estar 250 PS

An overhead conveyor consists of a single track containing carrier trolleys connected by an endless chain. Typical overhead conveyor applications insure product flowing through finishing operations such as paint booth, dip tank, plating operation, assembly line, etc… Lubrilog has developed a full suitable lubricant range dedicated to conveyor system to match technical and economical end users expectations. Our special lubricants perform in any conditions even in the extreme ones.

View productOur greases for robot reducers in car manufacturing industry: PE 1612

Industrial robots have now become a key part of your productivity and the reliability of your production. Lubrilog has developed a range of specific lubricants for the reducers of articulated robots. PE 1612 is a grease specificaly developped for the lubrication of articulated robot reducers like NABTESCO or SPINEA brands.

View productOur versatile range of hydraulic oils: Azolla

Hydraulic oils represent usually the main lubricant consumption in an automotive plant. Selecting the right lubricant and having the right reflexes on how to maintain your lubricants is a key to guarantee a long life for your equipments.

TotalEnergies Lubrifiants is producing all type of hydraulic fluids, which are homologated by main machine's producers: Azolla ZS which are mineral oil based hydraulic oils HLP with high oxidation stability for high working temperature, Azolla AF which are mineral oil based hydraulic oils HLP without zinc (ash-free version), in case of humid environment or sensitive equipments and Azolla DZF which are mineral oil based hydraulic oils HLPD, in case of water presence.

View productOur hydraulic oils for low temperature environment: Equivis

Equivis range is specifically designed to very low temperature environment, or for any outside operation. Equivis ZS are mineral oil based hydraulic oil HVLP, with an ultimate oxidation stability even at high temperature, Equivis AF are mineral oil based hydraulic oil HVLP without zind (ash-free version), for outside or low temperature operations and Equivis HE are high efficiency HVLP hydraulic oil, improving your press efficient by reducing the energy consumption up to 5%.

View productOur industrial gear oils: Carter

High pressure gear oil, adapted for high temperatures and in demanding environments. Carter EP is a mineral oil based specially designed for lubricating enclosed gears operating under severe conditions such as bevel and spur gears, bearings and gear couplings and worm gears. Carter SH is a premium range formulated with PAO base oils for the lubrication of any enclosed gears, bearings or gear couplings. Due to its unique technology, Carter SH can perform on a wide temprature range with the same efficiency and protection level.

Carter SG is formulated with synthetic PAG base oils and selected additives. Carter SG is a high efficiency product, improving the yield of your equipment and reducing the energy consumption.

View productOur high performance slideway oils: Drosera

Drosera MS offers a wide range of applications for all parts of machine tools (hydraulics, slides, gears). Formulated with premium quality base oils and specific additives, Drosera MS range can lubricate slideways under all conditions of speed and load. ISO grades 32 or 46 can be used either for hydraulic circuits, for the lubrication of pumps and motors. Light grades (ISO VG 5, 10, 15 and 22) are designed for the lubrication of high speed machine spindles.

Drosera MS is homologated by main OEMs and can be used in centralized lubrication systems.

View productOur multi-purpose greases for extreme pressure environment: Multis

Multis range is made of versatile greases from TotalEnergies Lubrifiants, based on a specific soap technology lithium/calcium and a specific selection of additives to guarantee a wide range of working temperature and a good performance in every condition, even in wet or dusty environment.

View productOur greases for extreme-pressure environment with high water and thermal resistance properties: Ceran

Ceran is made of the NEW GENERATION calcium sulfonate complex soap designed by TotalEnergies Lubrifiants. This new soap has enhanced properties in terms of water resistance, load capacity, thermal resistance, anticorrosion properties while keeping a very high level of pumpability and ability to lubricate well in case of high speeds.

Ceran is suitable for the lubrication of all kinds of components subject to high loads, shocks, working in conditions where the grease is in frequent contact with water (even sea water due to enhanced antirust performances) in transport, marine and offshore applications.

View productIndustrial applications for car manufacturing industry

Our services for industry professionnals

TotalEnergies Lubrifiants offers a wide range of services for industry professionals. From in use oil analysis to our TIG6 maintenance software (CMMS), our range of services is specifically designed to help you approach the management of your operations with confidence, allowing you to focus on what matters most: your production.

Latest News

-

18/02 2026